To facilitate customers in choosing the sealing liner that suit them, I will give a brief introduction about selecting the relevant structural materials of the aluminum foil sealing liner.

Selection of the liner sealing layer material:

The material of the sealing liner layer is selected according to the different materials of the sealed container, the different objects encapsulated, and the different effects that customers want.

For example, the PET heat-sealing layer of aluminum foil sealing liner can only seal PET material containers. PE heat-sealing layer of aluminum foil sealing liner can only be used for sealing PE material containers

If the encapsulated substance is volatile or highly corrosive, you need to use a high barrier aluminum foil sealing liner;

If the end-user requires easy-to-peel sealing aluminum foil, then it is necessary to use an aluminum foil sealing liner with an easy-to-peel sealing layer;

If the end-user needs a robust protective aluminum foil sealing liner, you must use aluminum foil liner with a reinforced sealing material.

Thickness of liner:

The thickness of liner is generally determined by the gap between the cap and the bottle. The bigger the gap between the lid and the mouth, the thicker the sealing liner backing should be used.

Diameter of liner:

The diameter of the sealing liner is usually about 0.5mm larger than the inner diameter of the cap.

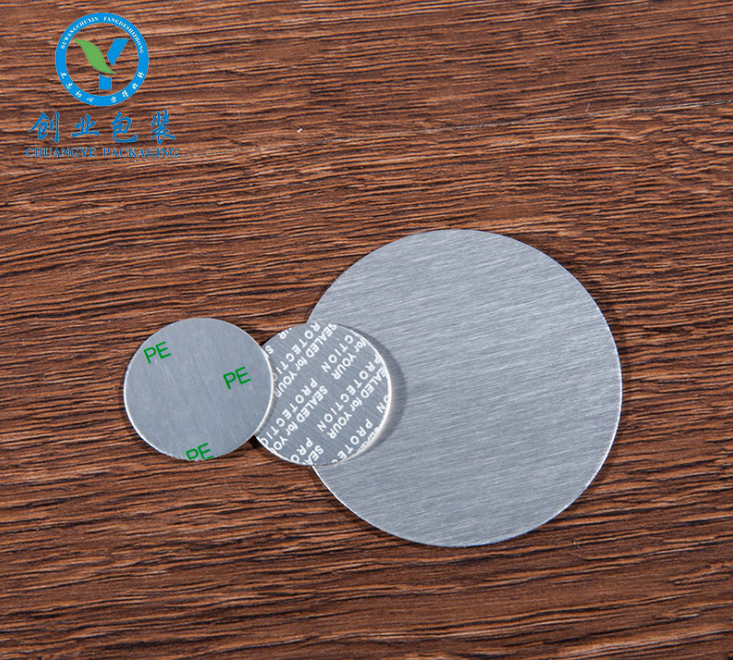

One-piece or two-pieces:

The one-piece aluminum foil sealing liner, that is, the sealing back lining foam and sealing aluminum foil layer, is still in one and covered in the mouth of the bottle;

Two piece aluminum foil gasket, that is, the gasket backing and sealing aluminum foil layer are combined into one by wax. The sealing back lining and sealing aluminum foil are divided into two. The sealing aluminum foil is bonded to the bottle mouth, and the backing is still in the bottle cap.